TRANSFORMING THE USES FOR CARGO AIRCRAFT

Founded nearly 30 years ago in San Antonio, exhibitor Knight Aerospace is building a global profile by developing an array of self-contained modular units and other products that can be quickly installed and secured in the cargo hold of different types of aircraft to meet different needs.

Basic units include palletized passenger seating, kitchen galleys and lavatories that significantly increase passenger comfort.

In recent years, the company has been at the forefront of integrating its aerospace expertise with medicine, resulting in the creation of the first-of-its-kind Aeromedical Bio-Containment Module (ABCM).

This self-contained, hospital-caliber medical module allows for the safe transport of highly contagious or critically injured patients on board of an array of large cargo aircraft. In addition, utilization of the patient area in the Module can be expanded to transport critical vaccines. It is the first fully airworthy modular system in the world, offering interoperability on the C-130 and C-17 and without the need for waivers.

The Royal Canadian Air Force (RCAF) is now using the new technology. It will also be capable to evacuate injured or critically ill troops from anywhere in the world and it will similarly support Canada’s international and domestic humanitarian missions.

Knight is in discussions with several other defense and non-governmental organizations who can benefit from the life-saving technology.

Interior of the medical module.

The first medical module as it is loaded onto a Royal Canadian Air Force aircraft at Kelly Field in early 2021 – ready to undertake life-saving missions in Canada and around the world.

Hermetically sealed and negatively pressurized with an independent air supply, the new technology protects the pilots and aircrew outside the module from infection. This also allows aircraft to be returned to service immediately upon unloading the ABCM by eliminating the need for costly and time-consuming decontamination of the plane.

The first completed module inside the Knight facility – located just half a mile from the industrial airport at Kelly Field.

The ABCM is outfitted with state-of-the-art medical equipment and offers a wide range of critical care capabilities. These allow for the treatment of ill patients while in flight, including performing emergency surgery.

Upon landing, the unit can continue operating on the ground, since all that is required is an electric supply such as a gas-powered generator. This capability allows for the expansion of field hospitals and other temporary medical facilities that are dealing with pandemic surges or other emergencies. The ABCM can also provide much-needed care to remote places that currently lack such facilities altogether.

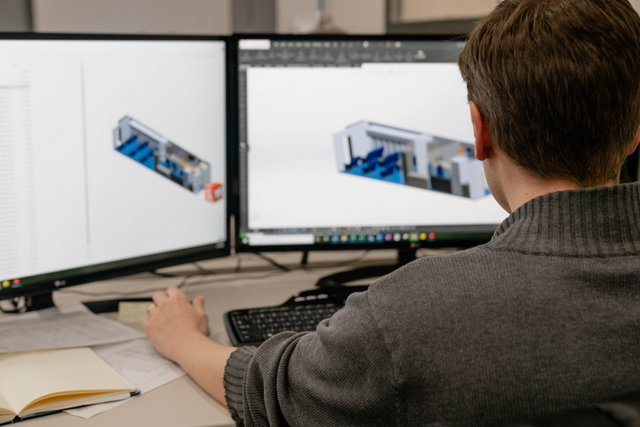

Knight’s modern new large space at Port San Antonio allows the company to conduct research, engineering, fabrication, testing and product demonstrations within a single facility.

The airworthiness of the new technology is assured as it has been built using the highest of military and FAA standards. Knight’s many platforms, including the ABCM, have been proven and certified over the course of the company’s history.

Knight’s in-house engineers and other personnel collaborated over many years with defense and medical experts to design and develop the life-saving technology.

As part of that development of the ABCM technology, the company worked in close alignment with numerous defense and medical organizations around the world, including the U.S. Centers for Disease Control (CDC), to develop a product that can provide the highest quality medical care while in flight and can be adapted to meet different needs.

The ABCM operates within different types of cargo aircraft. Shown is one of the unit’s first missions aboard a Royal Canadian Air Force C-17.

Knight began to build its expertise long before the current COVID-19 pandemic. Its medical team is led by Dr. Paul K. Carlton Jr., a retired U.S. Air Force Surgeon General who is one of the world’s top experts in medical evacuation. Among his accomplishments, he is the developer of Critical Care Air Transport Team (CCATT) currently used by the U.S. Air Force and military forces around the world and serves as an advisor to Knight. The company’s Chief Medical Officer, Dr. Jay Johannigman, is a colonel in the U.S. Army Reserves with decades of military medicine experience, including as a leading combat surgeon.

ABOUT KNIGHT AEROSPACE

Knight Aerospace leads the industry in the design, manufacture, and customization of medical modules, pallets, VIP transport systems, and more for cargo aircraft. These include a variety of quick-change, roll-on/roll-off products, like the Next Generation ATGL for military aircraft. Knight has delivered products to more than 34 countries since 1992.